sunirefox

-

Numero contenuti

102 -

Iscritto

-

Ultima visita

-

Giorni Vinti

1

Tipo di contenuto

Profili

Articoli

Introduzione alla stampa 3D

Database materiali

Forum

Calendario

Blogs

Gallery

Download

Store

Risposte pubblicato da sunirefox

-

-

Il 29/3/2020 at 09:35, sunirefox dice:

Giusto scusate, non prendetemi in considerazione sul sensore sono stato ottimista , ancora non mi è arrivato, comunque i voltaggi sono identici 6/36/300ma, ho misurato entrata e uscita sulla scheda e cisiamo come tensioni, adesso dovrei averlo in mano e tarare gli 0,8mm , comunque dei miei amici lo hanno installato su x5s e và alla grande , c'è anche da dire che loro hanno il marlin non ufficiale. Comunque appena ce l'ho in mano farò le prove del caso . Per ora sperimento io.

Provato e testato compatobile al 100%

-

Giusto scusate, non prendetemi in considerazione sul sensore sono stato ottimista , ancora non mi è arrivato, comunque i voltaggi sono identici 6/36/300ma, ho misurato entrata e uscita sulla scheda e cisiamo come tensioni, adesso dovrei averlo in mano e tarare gli 0,8mm , comunque dei miei amici lo hanno installato su x5s e và alla grande , c'è anche da dire che loro hanno il marlin non ufficiale. Comunque appena ce l'ho in mano farò le prove del caso . Per ora sperimento io.

-

Cambiate sensore ,io ho preso questo è identico sia di volt ma è capacitivo , no quella schifezza dell'originale

https://www.amazon.it/gp/product/B073SSM2YN/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1

-

provate adesso

-

qualcuno ha lo schema della scheda madre x5sa pro ?

-

provate adesso

-

Tronxy X5S

in Tronxy

a chi servisse datasheet x5sa pro

-

Tronxy X5S

in Tronxy

Whitedavil avevi ragione quella è una skr qui nada de nada per il marlin, finchè và

ho misurato tutte le tensioni di uscita, credo che il sensore sia compatibile al 99% per pro.

-

Tronxy X5S

in Tronxy

Si quindi la possibilità c'è. basta prendere i dati interessanti e inserirli in marlin 2.0.5 a 32 bit... credo

-

Tronxy X5S

in Tronxy

37 minuti fa, Whitedavil dice:Da elettronico con l'hobby della programmazione di cpu a 8bit e 32bit un po' so di cosa parlo. Comunque, se trovi un modo postalo, cosi potrà venire utile a qualcun'altro!

Dà un occhio qui perpiacere dovrebbe esserci la soluzione , visto che te la cavi con la programmazione , se c'è la soluzione allora postala x tutti noi.https://github.com/OrHavraPerry/TronXY-X5SA-Pro-Marlin/tree/master/Marlin-1.1.x

-

Tronxy X5S

in Tronxy

-

Tronxy X5S

in Tronxy

Adesso, Whitedavil dice:Da elettronico con l'hobby della programmazione di cpu a 8bit e 32bit un po' so di cosa parlo. Comunque, se trovi un modo postalo, cosi potrà venire utile a qualcun'altro!

Certamente che lo trovo e lo posterò ,mai dire mai l'impossibile divenne realtà ahahah

-

Tronxy X5S

in Tronxy

Ciao un conto e dire che bisogna configurare , un'altro è dire non è possibile che è sbagliato , perchè con le rep rap tutto è possibile basta solo studiarci un pò, e sai che ti dico prima o poi troverò la soluziobe ed il bl touch lo metterò .

-

Tronxy X5S

in Tronxy

Once again Scott Here to see if I can’t help you understand the something else I have seen questions about in the 3D printing community. This Time around I’ll go over the G-code used By Chitu on their F mini control board and other custom made control boards used by Tronxy and several other companies now. This control board comes on the Tronxy X5SA, X5ST, X5S-E2, XY-3 and XY-2 to name a few.

PLEASE NOTE CHANGING THESE SETTING WILL change your printers behavior. Therefore I do not recommend changing settings yourself without understanding what each setting your adjusting does.So To start with G code files can not be written in word you are better off writing then in notepad because it does not leave artifacts in the background. Therefore any time you want to update the firmware you need to either edit the g code you have or start a new notepad document for it.

I am going to do my best to explain each of the G codes in every day terms If I can think of how. Then if you want you canPerò stavo leggendo questo e questo parla di gcode

copy each line into a notepad document and edit and save it. Once saved to the SD card put the SD card into the control board and run that G code file as if it was a print and done. Make sure ever g code file you make has the save g code at the end.

Please not that this is the first G code I have seen that is like this “ M8012 I200” in this case the M8012 is the code then “ I” is the actual settings your adjusting so in the above example it is 200. The this example M8012 is the code for X Y max movement speed then the 200 is the mms. So if you wanted to slow down the max speed you could change it to 120 or 300 to speed it up depending on your printer.Resume on power Lose

M8000 I1 ; used if you have the resume on power lose module installed

M8000 I0 ; used if you do not have the resume on power lose module installed

Stepper Motor Direction

X stepper motor

M8002 I-1 ; current direction

M8002 I1 ; Reverse direction

Y stepper motor

M8003 I-1 ; current direction

M8003 I1 ; Reverse direction

Z stepper motor

M8004 I-1 ; current direction

M8004 I1 ; Reverse direction

E stepper motor

M8005 I-1 ; current direction

M8005 I1 ; Reverse direction

Movement configuration

X axis Movement

M8005 X0 ; print head moves in X axis

M8005 X1 ; Bed moves in X axis

Y axis Movement

M8005 Y0 ; print head moves in X axis

M8005 Y1 ; Bed moves in X axis

Z axis Movement

M8005 Z0 ; print head moves in X axis

M8005 Z1 ; Bed moves in X axis

Speed settings:

speed is in mm/s; acceleration is in mm/ s^2 start speed. When the moving speed exceeds this speed, it takes this speed as the starting speed and begins to accelerate.Otherwise, it is in constant motion at the moving speed

M8006 I120

JERK

M8007 I10 ; Lower this is your getting ringing

ACCLELERATION

Acceleration, the larger the value is, the greater the actual average moving speed is.

M8008 I1000

Axis Steps Per Millimeter

example, 1.8 degree stepper motor, pulley with 20 teeth, tooth pitch is 2.032mm, 1/16 microstepping are (20*2.032)/((360/1.8)*16)

Set X and Y the same

M8009 S0.0125 ; adjust the 0.0125 to correct both at once

independent X,Y stepper motor parameters

M8009 X0.0127 Y0.0127

Z axis

value of each step of Z. The calculation formula: lead /((360/1.8)*16),

M8010 S0.0025

Extruder Calibration

value of each step of E. This value is equal to the 1/3200 circumference of extruder gear. In addition

M8011 S0.010799

Max Movement / print speed

XY movement mm/s

M8012 I200

Z movement mm/s

M8013 I30

extruder mm/s

M8014 I120

Home Speed settings

first home speed

Z-axis

M8015 I8

X-axis and Y-axis

M8015 S30

second home speed

Z-axis returns

M8016 I4

X-axis and Y-axis

M8016 S5

Pre-extrusion before print

Pre- extruded

M8017 I10

max speed of pre-extrusion(mm/s)

Feeding by non-reduction gear, max speed always above 100.

M8018 I20

E max speed

Not sure why this one is here because M8014 does the same thing

M8019 I50

Retract

Distance

M8020 S1.5 ; will set the retract to 1.5mm no matter what the slicer says

M8020 S0 ; Follows slicer retract settingsSpeed

M8033 S8 ; will set retract speed to 8mms

M8033 S0 ; Follows slicer retract speed settings

Filament Diameter

M8021 S1.75

Max hotend temperature

M8022 I260

Min Hotend Temperature for extruder to turn on

M8022 T170

Maximum temperature of hot bed

M8023 I120

Temperature error detection

M8023 T0 ; Enable temperature error detection

M8023 T1 ; Forbidding temperature error detection

Maximum distance of X, Y, Z,

exceeding the distance will cause the buzzer to buzz

X

M8024 I330

Y

M8025 I330

Z

M8026 I439

number of extrusion head Or use of second E stepper driver If the second driver chip set is there. (tronxy E2 versions only)

Set the number of extrusion headat least 1, at most 3 at present

M8027 I1

Whether it is 3 in 1 out nozzle or 2 in 1 out nozzle, these two nozzles share a temperature sensor, share a heating rod

0: not 3/2 in 1 out nozzle 1: 3/2 in 1 out nozzle

M8027 S0

The second extrusion head will be used as Z. For some large equipment, two Z axes will be needed. Therefore E2 can be used as Z axis.

This order will force the number of extrusion heads to be 1 0: double Z double limit mode, the second limit connect to X+,

1£ºdouble Z single limit mode, only connect to one limit switch . if to enable this function, place a tick in front of the command.M8027 Z0

the second extrusion head will be used as Y

if to enable this function, place a tick in front of the command.

M8027 Y0The second extrusion head is used as the first one, because some machines use two motors to feed the wire

If you need to enable this feature, place a tick in front of the command

M8027 E0Heated Bed

M8027 T1 ; enable hot bed

M8027 T1 ; disable hot bed

Advanced Settings

Extra pri after retract

M8028 S0.00 ; Add to the 0.00 to add extra length on the prime length after retract.

Home location

M8029 I0 ; front left

M8029 I1 ; Unilateral maximum point limit

M8029 I2 ; Bilateral limit

M8029 I3 ; Limit in the left rear of the machine

types for limit switch

M8029 T0 , limit switch normally open, when not triggered, the signal level is open

M8029 T1:XYZ limit switch normally closed, when not triggered, the signal level is closed

Filament out Detection

Uses same plus as auto bed level sensor

M8029 D0 ; ban fault detection

M8029 D1 ; enabled fault detection

Limit switch type for filament out detection

M8029 P1 ; same with XYZ limit type

M8029 P-1 ; opposite to XYZ limit type

part cooling Fan

M8030 I0 ; fan is controlled by slicing software

M8030 Ixxx ; setting a temperature that is larger than 0 fan controlled by firmwareColdend Fan

M8030 I0 ; full speed from powering on control board

M8030 I50 T-1 ; allows you to set what speed and temp the coldend fan comes on at

SD card displayed on screen

M8034 I1 ; Yes

M8034 I0 ; No

Auto level point setup

The maximum is 5 as regard to leveling setting, X, Y are floating number, if X, Y are small than 1, then it indicates the corresponding proportion of journey. Otherwise, it indicates the absolute coordinates of X and Y, the unit is mm.

M8035 I3 ; the number of instruction is same with that of point

M8036 X-20 Y0 ; start point

M8036 X50 Y50 ; second point

M8036 X250 Y250 , Third point

M8036 X£» ; ends auto level

Machine type

M8080 I0 ; Cartesian

M8080 I2 ; Corexy

Thermistor type

M8081 I0 ; Ideal NTC 100K 1% 3950 B

M8081 I2 ; corresponding to the type 2 sensor of marlin

Auto leveling setting

M8083 I0 ; ban auto leveling

M8083 I1; enable auto leveling (leveling switch connect Z)

Z Height Offset(TORONXY HAS THE ONSCREEN)

I skipped this because Tronxy has it onscreen. Height difference of Z leveling limit = Z zero position-Z position for leveling limit. 0: forbid deviation, the route of Z is determined by¡°set Z as zero¡±,the printed

G code doesn’t need the automatic high leveling order. It's recommended to use this mode. Non 0:Z is automatically determined when the leveling limit is triggered. Under this mode,

G29 automatic leveling order must be after the return to zero of G28 and before begin print. If the extrusion head is near to main board during limitation, the value is positive.

M8084 Z4

Boot Screen

The minimum is 100ms,the maximum is 6000ms

M8085 I500

standby mode to shutdown

This function can only be used for the equipment installed with the power module. The unit is second(s). When the value is 0, it indicates forbidding the function of shutdown after standby.

M8085 P0

Max Fan speed

Max 256 with more noise, which can be adjusted through this parameter

M8489 I256

Disable steppers and turn off all heating after printing

M8489 P0 ; Turn off all

M8489 P1 ; G Code Controlled

PID

I have not used these one will more than likely be hotend the other the bedM301 P22.2 I1.08 D114 ; enables PID

M303 E0 S150 C5; enables PID

Laser Engraver

M8520 I0 ; do not support the laser engraving

M8520 I1 ; support laser engraving, there are more buttons inside to set speed

Wifi Setup

Replace the word networkname with your network's name leaving the quotation marks, Replace the word Password with your networks password leaving quotation marks.

M9005 '"Networkname","Password"'SAVE

MUST DO THIS IN EVER G CODE SET YOU SEND THE PRINTER

M8500

below is an example of a Gcode I personally used to do basic update to the X5SA.

;Speed settings: speed is in mm/s; acceleration is in mm/ s^2

;start speed.When the moving speed exceeds this speed, it takes this speed as the starting speed and begins to accelerate.

;Otherwise, it is in constant motion at the moving speed c3d

M8006 I120

; ==================================

;

;JERK

;

;maximum speed while turning a corner. There there will be a large number of reciprocating motion while filling.

;The noise is loud while this value is large. When the value is small, the speed is slow c3d

M8007 I10

; ==================================

;ACCLELERATION

;

;acceleration, the larger the value is, the greater the actual average moving speed is.

;However, the noise is loud. The actual speed is small when the value is small c3d

M8008 I3000

; ==================================

;MAX MOVEMENT / PRINT SPEED.

;

;maximum speed of various parameters. In order to ensure the stabilization of the machine,

;please make settings according to the measured results

;maximum speed of XY movement mm/s

M8012 I200

; ==================================

;maximum speed of Z movement mm/s

M8013 I30

; ==================================

;maximum speed of the extruder mm/s

M8014 I120

; ==================================

;Z-axis home speed.When using makerware software,the home speed will be ignored while slicing,

;because gcode specified the home speed

;first home speed when Z-axis returns to zero, higher

M8015 I8

; ==================================

;first home speed when X-axis and Y-axis returns to zero, higher

M8015 S30

; ==================================

;second home speed when Z-axis returns to zero, slower

M8016 I4

; ==================================

;second home speed when X-axis and Y-axis returns to zero, slower

M8016 S5

; ==================================

;Thermal Protection.

;

; Tronxy Has this turned off

;Forbidding temperature error detection. The default temperature error detection will pop up the warning when the temperature

;sensor is not well plugged in or the heating power is too small. Strongly suggest not forbidding this function

;1: Forbidding temperature error detection 0: Enable temperature error detection

M8023 T0

; ==================================

;MAX TRAVEL (adjusted because I have bed lowering installed).

;

;maximum distance of Z

M8026 I439

; ==================================

;the duration of the boot screen,the minimum is 100ms,the maximum is 6000ms c3d

M8085 I500

; ==================================

M117 PRINTER NOW CUSTOMIZED

;SAVE

;

;¡¾Save command¡¿ This parameter must not be less, otherwise all parameters can not be saved to the device

;save the configuration

M8500 -

Tronxy X5S

in Tronxy

si sto aspettando la cinghia chiusa, ho già preparato gli assi per la cinghia, però in alto questo non guasta, comunque credo che il firmware si possa cambiare cioè sbloccare la eprom però ancora nn sò come si fà, ma per il bl touch spero che basti il gcode

-

Tronxy X5S

in Tronxy

Io stavo leggendo qui e mi pare che tutto si possa fare , ma se non erro credo che basti un gcode :

-

Tronxy X5S

in Tronxy

2 minuti fa, I3D&MLab dice:Bel lavoro @Whitedavil ! 🙂

Quindi che mi dici si può fare ?

-

Tronxy X5S

in Tronxy

trovato su thi, tradotto alla buona per tutti coloro compreso me che sbotta sempre per gli assi z prima della grande modifica. Recita questo:

Il letto Tronxy X5SA continua a perdere l'allineamento tra le due viti Z ... E a volte piace schiacciare l'ugello sul letto. Questi semplici tappi a Z funzionano come un incantesimo per ripristinare l'alligamento, si alzano dal letto fino a quando gli stepper iniziano a saltare e il gioco è fatto! (il rumore non è così elegante, ma innocuo ...) Per la mia stampante, TronXY X5SA 24v 2019 l'altezza del tappo era di 28,5 mm ... Basta allineare il letto, spostare l'ugello per toccare il letto ... e misurare lo spazio vuoto e ridimensionare l'altezza di stampa allo "spazio vuoto - 1mm" ... -

Tronxy X5S

in Tronxy

-

Tronxy X5S

in Tronxy

-

Tronxy X5S

in Tronxy

1 ora fa, Whitedavil dice:Io ho il bltouch e ti posso aiutare a configurare il fw, se sulla tua elettronica è possibile. Ma il supporto te lo devi creare e stampare. Io sulla mia ho montato un estrusore direct per cui non ti posso passare un supporto.

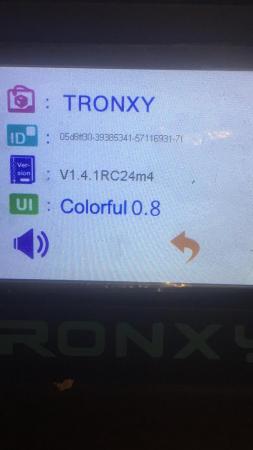

Si grazie di cuore, ho X5Sa pro 330x330x400, scheda 32 bit Arm3 driver 2256 , adesso mi metto alla ricerca del stl bltouch,

-

Tronxy X5S

in Tronxy

2 minuti fa, Whitedavil dice:Auguri ad integrare quel sensore, non so se hai notato ma 18mm di diametro. Il flusso lo regoli in base a come vengono le stampe, un 10% in più non è poco...

Dici che è difficoltoso da integrare? ho anche 2 bltouch disponibili però ancora nn ho informazioni a riguardo su bl touch e poi non trovato neanche il pz da stampare x adattare il bltouch, hai per caso 1 dei 2 o tutti e due?

-

Tronxy X5S

in Tronxy

stampa molto bene ma devo lavorare sulla retrazione, ancora un pelino e poi è perfetta reatrazione 8,40, flusso di riempimento sta a 100 ora io ci metterei 110 cosa mi consigliate?

-

Tronxy X5S

in Tronxy

comunque il fanduct io l'ho stampato in petg e anche da un pò di tempo per il momento nn ha ceduto sperem

Pezzi di ricambio

in Tronxy

Inviato

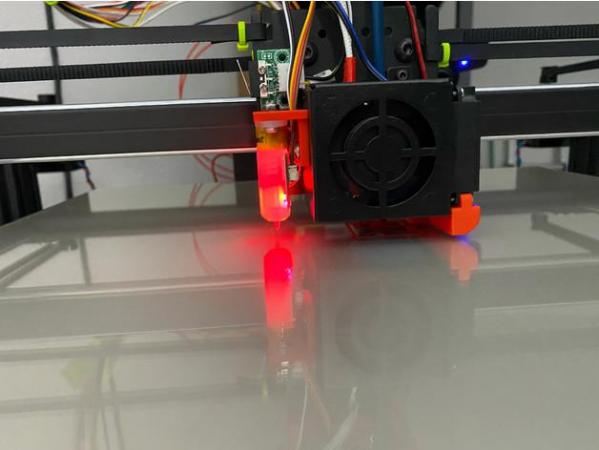

stampa su vetro. per chi diceva che non stampa su letto caldo, per chi diceva che ha dato problemi. và alla grande.